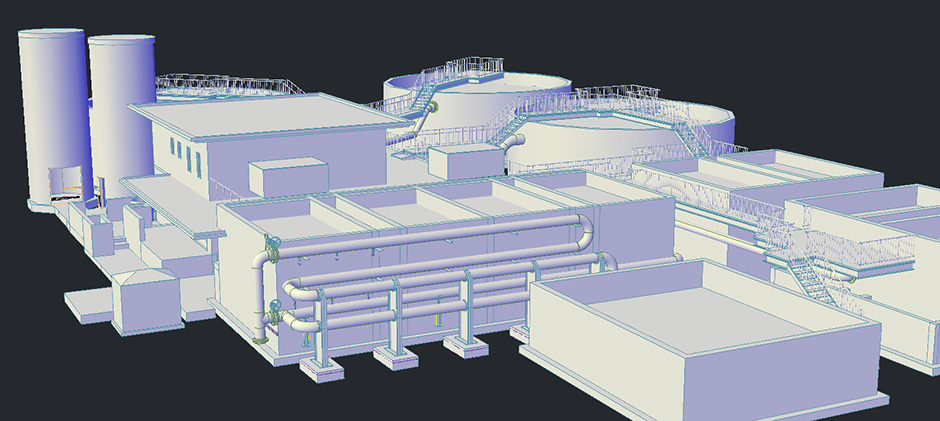

After a condition assessment of the Palm Bay Water Treatment Plant was performed by Wade Trim, large diameter process pipes were identified for replacement due to a high risk of failure. Used to convey filtered water from the lime softening treatment units to the sand filters and ground storage tank, these 16- to 24-inch diameter, welded steel pipes had reached the end of their useful life. An ultrasonic inspection revealed that less than half of the original pipe thickness remained at 40% of the 92 inspection locations.

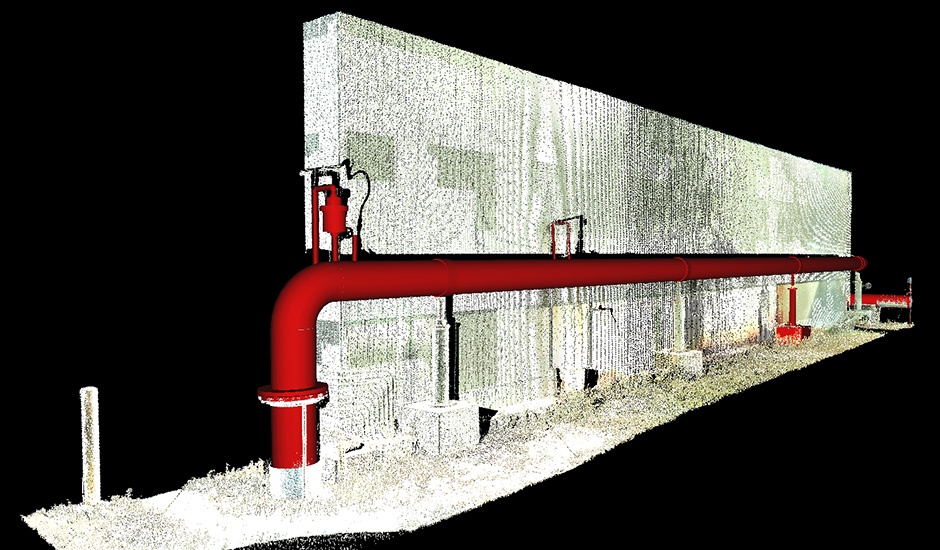

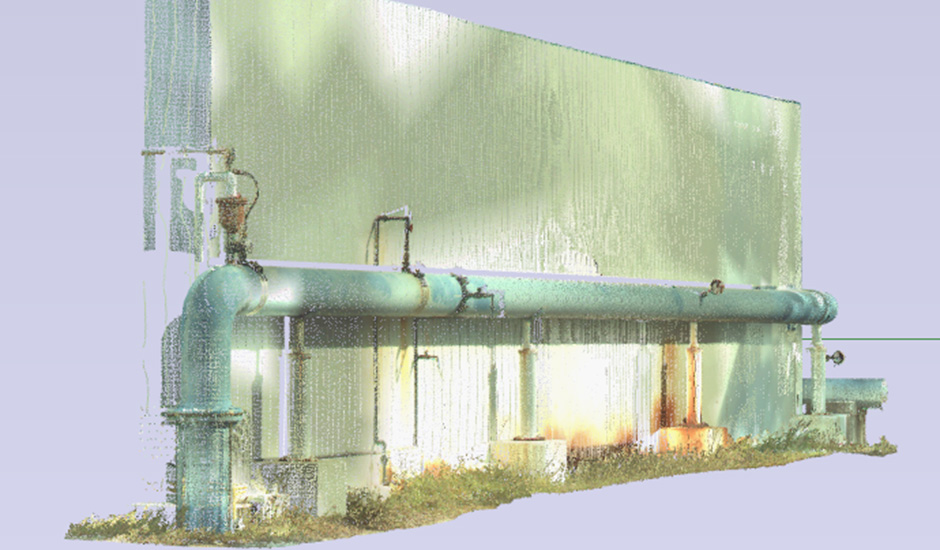

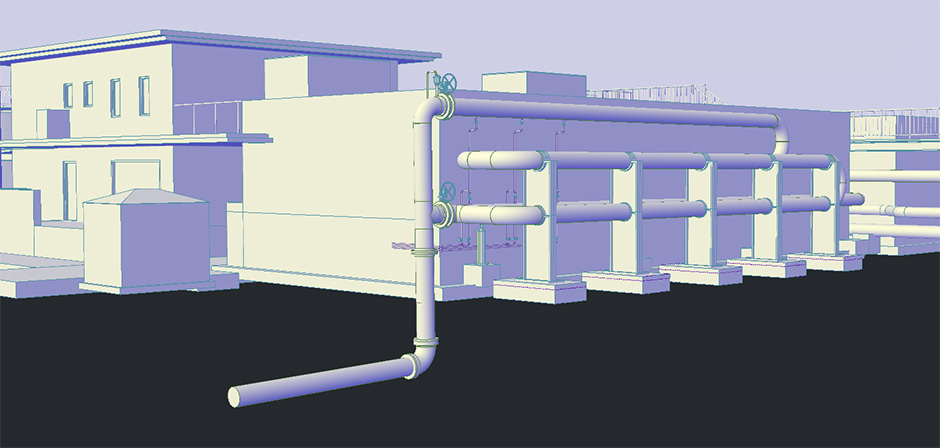

Designing within the complex pipe geometry and frequent bends required a 3D approach to improve accuracy and efficiency. The process involved laser scanning the entire facility and using the data to create a 3D model of the plant. The model helped identify conflicts with other pipes and equipment, generated highly accurate material costs, and enabled City staff to easily visualize the final project. Nearly 80% of the pipe was replaced in the same location in segments, temporary chemical injection points were added, and additional pipe was installed to help reduce the formation of disinfection byproducts. Steel was selected as the preferred material based on its suitability for lower pressures, light weight and low cost. Construction was sequenced in five phases to maintain continuous plant operations.